Helium leak testing is a critical quality control process in the automotive industry, ensuring the safety and performance of vehicle components such as fuel systems, air conditioning units, and brake lines. As helium supplies become increasingly scarce and costs continue to rise, automotive manufacturers need to maximise efficiency in helium leak testing. In this article, we provide a comprehensive guide to leak test optimisation, highlighting the importance of advanced helium recovery and purification systems like VES’s PURE.

Assess and Optimise Test Parameters

The first step in maximising efficiency in helium leak testing is to assess and optimise the test parameters. This includes evaluating factors such as test pressure, helium concentration, and test duration to ensure that the leak testing process is both accurate and efficient. Automotive manufacturers should work closely with their leak-testing equipment suppliers to determine the optimal parameters for their specific applications, balancing the need for accuracy to reduce helium consumption.

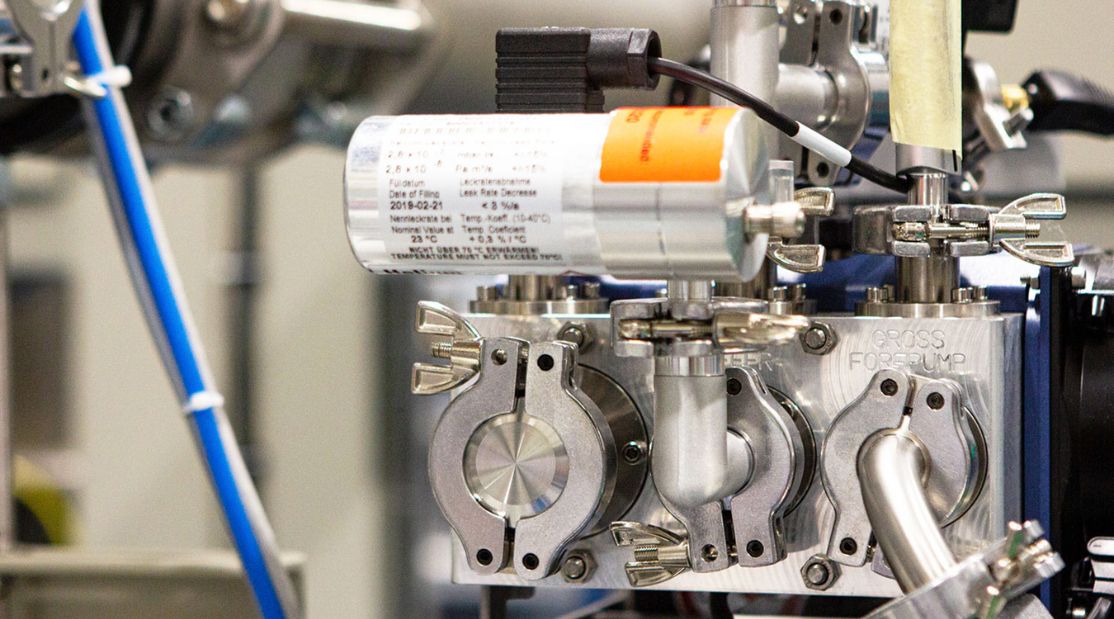

Invest in Advanced Leak Detection Equipment

Utilising state-of-the-art leak detection equipment can significantly improve the efficiency and accuracy of helium leak testing processes. Modern leak detectors offer improved sensitivity and faster response times, allowing manufacturers to identify and address leaks more quickly and effectively. Additionally, advanced leak detectors often feature user-friendly interfaces and data management capabilities, streamlining the testing process and facilitating continuous improvement efforts.

Implement a Helium Recovery and Purification System

One of the most effective ways to maximise efficiency in helium leak testing is to implement a helium recovery and purification system. These systems capture and recycle helium used during the testing process, reducing the need for fresh helium supplies and minimising waste. VES’s PURE Helium Recovery and Purification System is a leading example of such a system, offering unparalleled helium recovery and purity rates, seamless integration with existing leak testing machines, and minimal impact on production cycles.

Regularly Maintain and Calibrate Testing Equipment

To ensure optimal performance and efficiency, it is crucial to regularly maintain and calibrate helium leak testing equipment. Proper maintenance helps to prevent equipment malfunctions and downtime, while calibration ensures that the leak detectors remain accurate and reliable. Automotive manufacturers should establish a routine maintenance and calibration schedule in collaboration with their equipment suppliers to keep their leak-testing processes running smoothly and efficiently.

Train and Educate Personnel

The efficiency of helium leak testing processes is heavily dependent on the skills and knowledge of the personnel involved. It is essential to provide ongoing training and education for operators, engineers, and quality control staff, ensuring that they are up-to-date on best practices and the latest advancements in helium leak testing technology. By fostering a culture of continuous learning and improvement, automotive manufacturers can enhance the efficiency and effectiveness of their helium leak testing processes.

Maximising efficiency in helium leak testing is essential for automotive manufacturers as they navigate the challenges posed by the global helium shortage. By optimising test parameters, investing in advanced leak detection equipment, implementing helium recovery and purification systems like VES’s PURE, and prioritising maintenance, calibration, and training, manufacturers can ensure the accuracy and efficiency of their helium leak testing processes while reducing costs and conserving valuable helium resources.