If you are searching for a Helium Leak Test Procedure you can adapt to your own production line, this sample is designed to give you a clear starting point. While every facility will have its own unique requirements, this example outlines the core structure and steps you should include for accurate and repeatable results.

Sample Helium Leak Test Procedure

- Scope

This procedure describes the method for performing helium leak testing on [component name] to ensure it meets the maximum allowable leak rate of [specify value] mbar·l/s. - Purpose

To verify the integrity of parts using helium as a tracer gas, ensuring compliance with [insert relevant standards, e.g. R134 or customer-specific requirements]. - Equipment Required

- Helium mass spectrometer leak detector

- Tracer gas cylinders (pure helium or helium-nitrogen mix)

- Vacuum pump

- Test chamber or fixture with appropriate seals

- Calibrated reference leak device

- Data logging system

- Part Preparation

- Clean and dry the component to remove debris, oil, and moisture

- Seal all ports except the one used for pressurisation

- Confirm part ID and record in test log

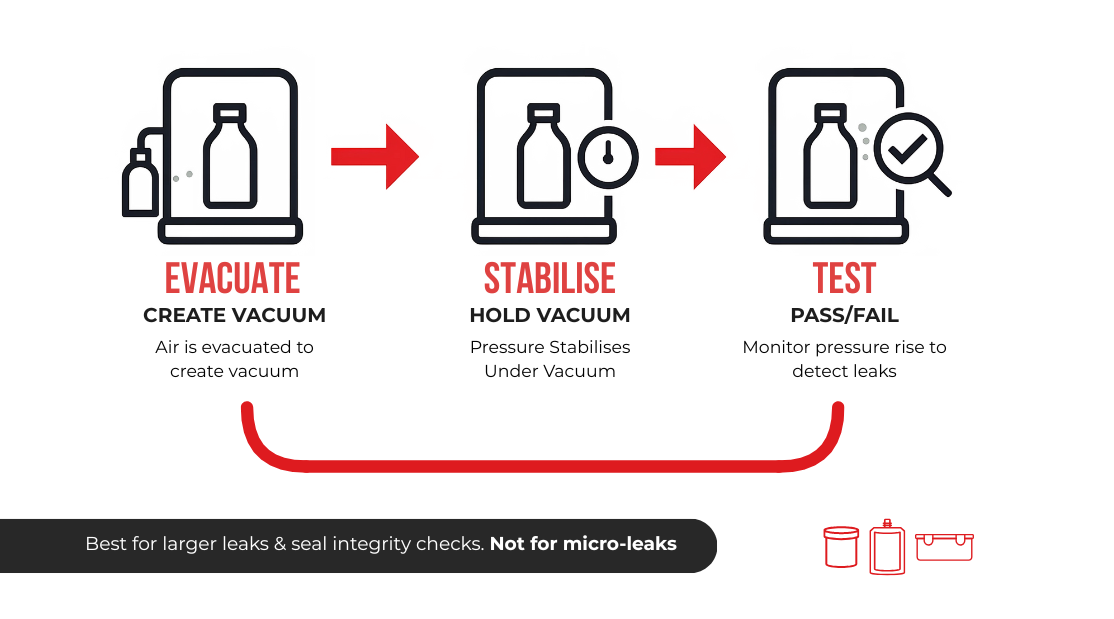

- Test Method

- Select the vacuum chamber method for maximum sensitivity

- Evacuate the chamber to [specify vacuum level]

- Pressurise the part with tracer gas to [specify pressure] bar

- Allow a dwell time of [x] seconds for stabilisation

- Measurement

- Begin helium detection using the mass spectrometer

- Monitor for helium ingress and record the peak leak rate

- Compare results against the pass/fail criteria

- Pass/Fail Criteria

- Pass: Leak rate ≤ [specified value] mbar·l/s

- Fail: Leak rate > [specified value] mbar·l/s

- Data Recording

- Log part ID, operator ID, date, leak rate, and result

- Store data for at least [x] years to maintain traceability

- Calibration

- Perform calibration checks at the start of each shift using the reference leak

- Record calibration results in the maintenance log

Why a Custom Helium Leak Test Procedure Matters

This Helium Leak Test Procedure is only an example. The best results come from tailoring each step to match your exact components, test methods, equipment, and environmental conditions. Using a generic procedure without adjustment can lead to false passes, unnecessary fails, and inconsistent data.

At VES, we help manufacturers develop Helium Leak Test Procedures that are accurate, compliant, and practical for daily use. Our approach ensures your operators can follow the steps easily while meeting both production and regulatory requirements.