If you’re in HVAC manufacturing, you already know leak testing is essential. Every part has to be sealed tight before it leaves the line. But when it comes to picking the right HVAC leak testing equipment, things can get complicated fast.

There are a lot of options out there. Some systems are fast but not flexible. Others promise precision but take up half your factory floor. And then there’s the challenge of balancing budget, compliance, and future growth.

So how do you make the right choice? It starts by asking the right questions.

What Kind of Parts Are You Testing

Let’s start with the obvious. Not all HVAC components are the same. You might be testing small coils one day and large condenser units the next. Some parts operate under higher pressures or require tighter tolerances.

That means your testing equipment needs to be flexible enough to handle a variety of shapes, sizes, and specs. If your product range is simple, a dedicated system might do the trick. But if you work with multiple variants or plan to expand, modular equipment is a smart move.

At VES, we design systems that can easily adapt to new models without needing a complete overhaul.

How Sensitive Does Your Testing Need to Be?

Different refrigerants come with different leak rate requirements. If you’re working with CO2 (R744) or next-generation refrigerants like R1234yf, your tests need to be more precise.

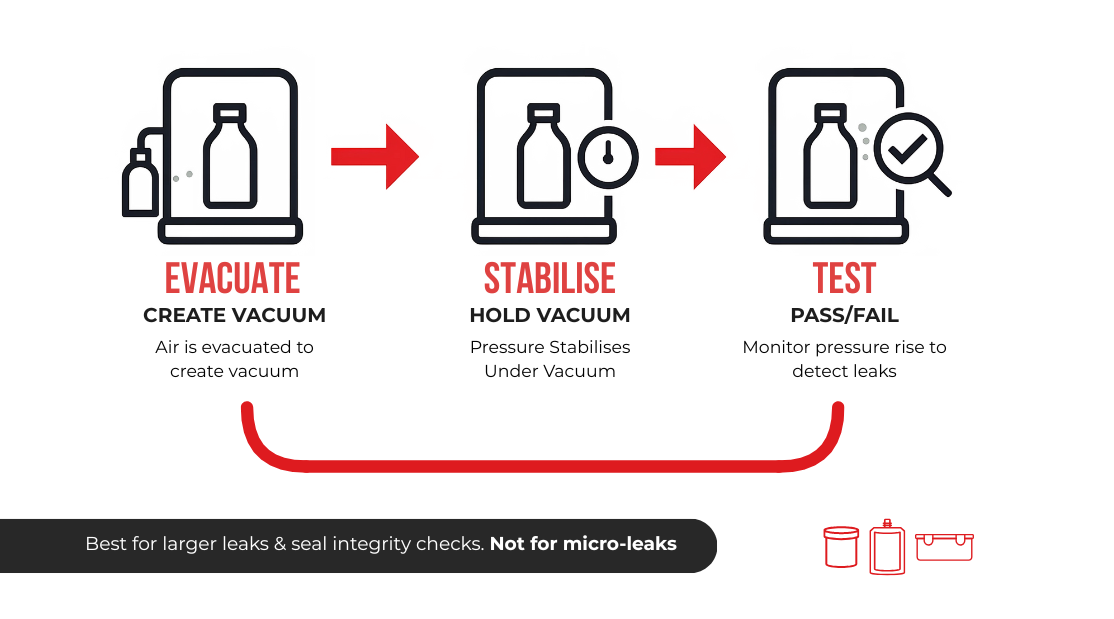

That rules out older methods like bubble testing or basic pressure decay. These might catch big leaks, but they often miss the small ones that can still cause problems.

If you need tight tolerances, helium leak testing is usually the way to go.

How Much Space Do You Have?

This one gets overlooked all the time. You find the perfect system, then realise it needs more room than your line can offer. Suddenly, you’re stuck choosing between a full reconfiguration and settling for something less effective.

Make sure the system you choose actually fits into your workspace. Compact designs, easy integration with automation, and minimal support infrastructure are key.

Our equipment is built with real-world factory floors in mind. Small footprint. High performance. Easy to install and maintain.

What Happens After the Test?

Testing is only part of the job. You also need to capture data, meet compliance standards, and keep your team trained and confident.

Ask whether your testing system includes:

- Data logging for traceability

- Easy-to-use interfaces

- Service and support you can count on

- Training for new operators or process changes

We know how fast things move in HVAC production. That is why we build all of these features into our systems from the start. And our global support teams are always ready to help.

Can Your Equipment Grow With You?

Right now, you might be producing 100 units a day. A year from now, it could be double that. Make sure your leak testing system can scale with your business.

Look for modular equipment that allows you to add new stations or adapt to different part designs without a complete rebuild. This kind of flexibility saves time and money long term.

Our systems are designed to grow with you. Whether you’re expanding your line or switching to a new refrigerant standard, we make sure your leak testing never becomes a bottleneck.

Making the Right Choice

Selecting the right HVAC leak testing equipment is not just about specs. It is about choosing a system that fits your products, supports your goals, and keeps your operation moving.

At VES, we do more than supply machines. We work closely with you to understand your process, production needs, and compliance targets. Then we build a system that does the job properly without adding unnecessary complexity.

If you’re ready to upgrade your testing capabilities or plan a new line, let’s talk. We’ll help you make a decision that works today and continues to work as you grow.