Leaks in HVAC systems are a common cause of reduced efficiency, increased energy costs, and equipment failures. For manufacturers, ensuring leak-free components is essential for meeting performance standards and regulatory compliance. That’s why many turn to Sniffer Leak Testing HVAC Systems as a reliable and precise method for quality assurance.

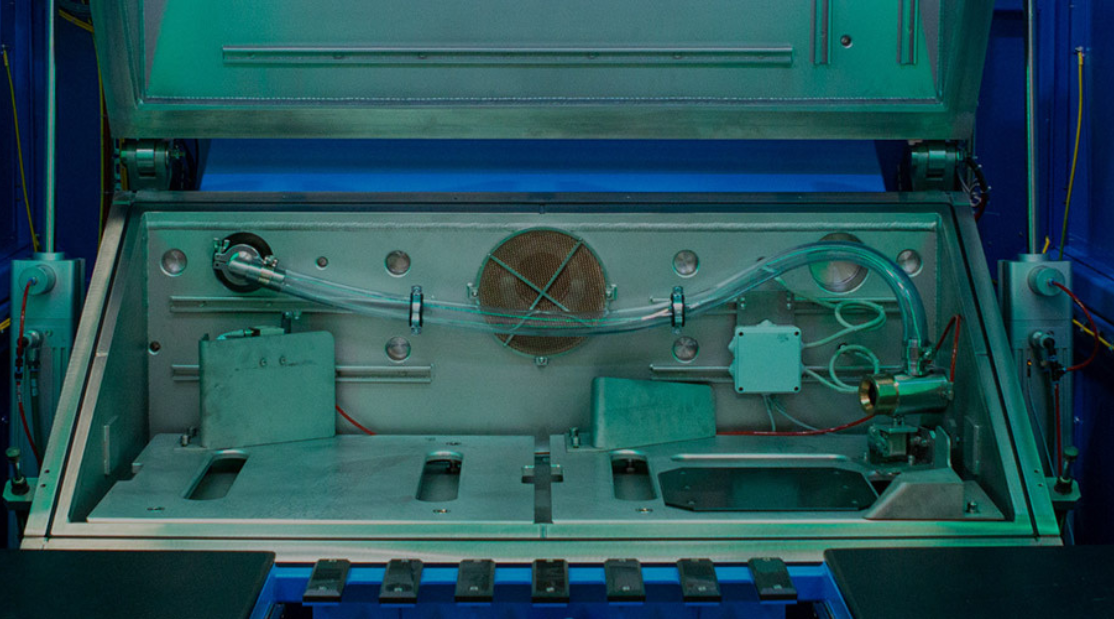

At VES, we design and manufacture high-performance sniffer leak detection systems that HVAC manufacturers use to carry out this essential process. Our machines are built to deliver accuracy, repeatability, and efficiency in demanding production environments.

What Is Sniffer Leak Testing?

Sniffer leak testing involves detecting trace amounts of gas escaping from pressurised HVAC components. After filling the part with helium or a forming gas mixture, a sniffer probe is used to locate the source of any leaks. This method is especially effective for components that are too large for vacuum chambers or when an exact leak location is required.

Why Choose VES Sniffer Systems for HVAC Manufacturing

Our sniffer leak detection machines are trusted by leading HVAC manufacturers worldwide. Designed specifically for production lines, they support high-speed testing of coils, condensers, evaporators, and other HVAC components.

Here are the core benefits of choosing VES:

- Exceptional Sensitivity: Detects even the smallest leaks to support compliance with SEER and F-Gas regulations.

- Modular Design: Easily scalable to suit low or high-volume production without requiring system replacement.

- Compact Footprint: Saves valuable floor space, allowing for tight line integration and streamlined workflows.

- User-Friendly Interface: Reduces operator training time and ensures consistent testing across shifts.

Our machines are engineered to help manufacturers avoid rework, reduce helium usage, and maintain high production throughput with minimal downtime.

The Process of Sniffer Leak Testing HVAC Systems

When using our machines, the leak testing process is both simple and highly effective:

- Pressurise the Part: The HVAC component is filled with helium or forming gas to the specified test pressure.

- Sniff for Leaks: The operator or robotically controlled sniffer scans joints, welds, or seals for escaping gas.

- Detect and Report: The system captures real-time data, flags any failures, and logs test results for traceability.

- Review and Act: Operators can immediately locate and repair leaks before components move further down the line.

This method ensures each part meets strict leak rate limits and reduces the risk of downstream failures or warranty claims.

Supporting Quality, Compliance, and Cost Efficiency

Our sniffer systems are ideal for manufacturers who need precision without compromising on speed or space. Our solutions have been installed in production facilities across Europe, Asia, and North America, helping customers improve product quality, meet international standards, and reduce total cost of ownership.