Hydrogen is leading the charge towards a cleaner energy future, but it’s safe storage is essential. One of the key metrics in ensuring the reliability of hydrogen storage vessels is a high Process Capability Index (CPK) – a measure of manufacturing consistency.

A CPK of greater than 1.67 is the gold standard in this field. It means the product consistently meets quality standards with minimal deviation. For hydrogen storage vessels, this translates to exceptional safety and performance.

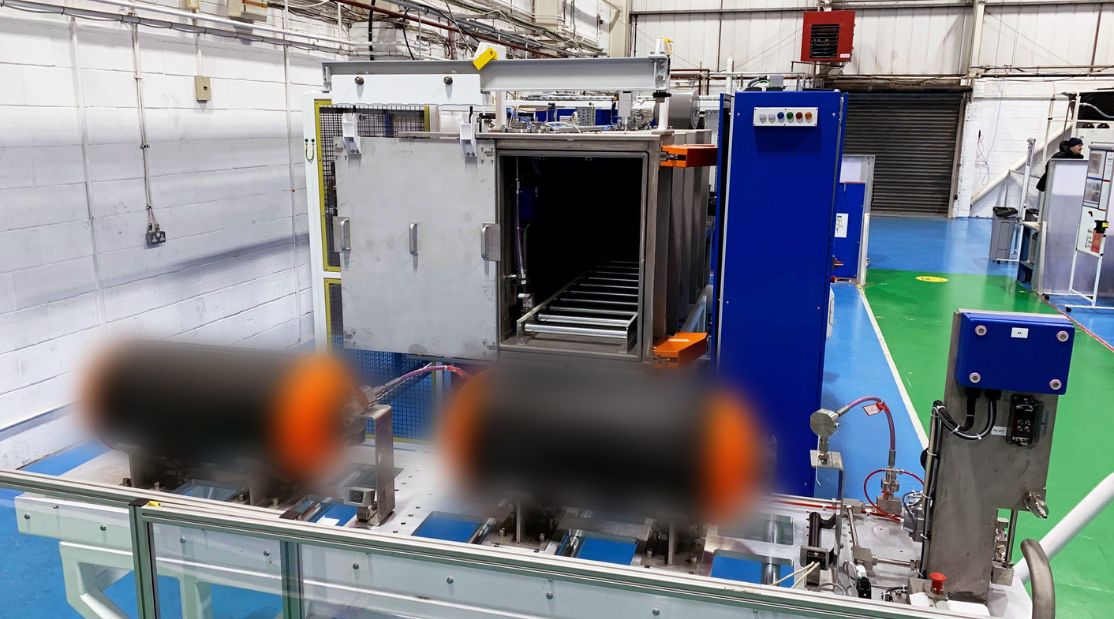

At VES New Energies, our leak-testing systems are designed to meet and exceed these stringent requirements. By adhering to pressure regulations, we guarantee that our vessels are leak-free and reliable, providing you with the confidence and peace of mind.

The Importance of a High Process Capability Index (CPK)

The Process Capability Index (CPK) is a statistical tool used to measure a process’s ability to produce output within specified limits consistently. A CPK value greater than 1.67 indicates a highly capable process, meaning the production of high-quality components with minimal defects. In the context of manufacturing high-pressure hydrogen storage vessels, this is critical. These vessels must withstand extreme conditions and pressures, necessitating rigorous quality control to ensure their safety and performance.

Hydrogen storage vessels are typically composite materials, combining high-strength carbon fibres with a polymer liner. These materials must be manufactured with precision to meet stringent safety standards. A high CPK ensures that the production process is stable and capable of consistently producing vessels that meet these exacting standards.

Ensuring High Standards

Our leak-testing system is designed to uphold these high standards in the manufacturing process. Certified to meet international standards such as R134 and TCATSI, our system offers precise and reliable leak detection. This ensures that each hydrogen storage vessel produced is leak-free and compliant with global safety regulations.

Compliance with Pressure Regulations

The compliance with pressure regulations is a fundamental aspect of maintaining a high CPK. Our system is designed to test hydrogen storage vessels at pressures ranging from 350 to 875 bar, ensuring they can withstand the operational stresses they will face in real-world applications. The system’s adherence to standards like R134 and TCATSI ensures that the vessels meet both national and international safety requirements.

Certified to Meet Stringent Standards

Our leak-testing system’s certification to R134 and TCATSI standards demonstrates its capability to meet the rigorous demands of hydrogen storage vessel manufacturing. R134, a regulation from the Economic Commission for Europe, outlines the safety requirements for the on-board storage of hydrogen. Similarly, TCATSI sets the standards for the type, parameters, and testing methods for fully-wrapped carbon fibre reinforced cylinders with a plastic liner for hydrogen storage. By complying with these standards, we ensure that hydrogen storage vessels are safe, reliable, and ready for use in various applications.

Modular and Flexible Design

The New Energies modular and flexible design is another key feature that supports achieving a high CPK. This design allows manufacturers to customise the system to meet specific production demands, optimising costs and lead times. As production needs evolve, additional modules can be integrated into the system, ensuring that it remains scalable and future-proof.

Traceable Calibrated Leaks

The use of traceable calibrated leaks in our system provides an added layer of assurance. These calibrated leaks ensure that the leak detection process is accurate and repeatable, further supporting the goal of achieving a high CPK. By verifying the system’s performance against known standards, manufacturers can be confident in the reliability of their leak detection processes.

The Role of CPK in Quality Assurance

Achieving a CPK greater than 1.67 is a testament to a manufacturing process’s quality and reliability. For hydrogen storage vessels, this means that the vessels are not only safe but also consistent in their performance. This consistency is essential for applications where the failure of a storage vessel could have catastrophic consequences.

Enhanced Safety and Compliance

A high CPK translates to enhanced safety and compliance with regulatory standards. Hydrogen storage vessels must operate under high pressures and harsh environmental conditions. Any deviation from the specified quality can lead to leaks, which are unacceptable in hydrogen storage due to the explosive nature of hydrogen gas. By maintaining a high CPK, manufacturers can ensure that their vessels are safe and compliant with all relevant regulations.

Reduced Recalls and Increased Confidence

Maintaining a high CPK also reduces the likelihood of product recalls, which can be costly and damaging to a company’s reputation. By ensuring that each hydrogen storage vessel meets the highest standards of quality, manufacturers can ship their products with confidence, knowing that they are delivering safe and reliable components to their customers.

Achieving High CPK for Hydrogen Storage Vessels

Achieving a Process Capability Index greater than 1.67 is essential for the manufacturing of high-pressure hydrogen storage vessels. Our New Energies leak-testing system plays a vital role in maintaining this high standard. By complying with international standards like R134 and TCATSI, offering a modular and flexible design, and using traceable calibrated leaks, our system ensures that hydrogen storage vessels are produced with the highest levels of precision and reliability. This commitment to excellence not only enhances safety and compliance but also reduces recalls and increases customer confidence, driving the hydrogen energy sector towards a safer and more sustainable future.