We recently welcomed more of our engineers from Mexico, along with their customers, to witness the factory acceptance testing of our bespoke helium leak testing systems. These systems are specifically designed for testing the next generation of aluminium coils used in air conditioning units. These coils are produced by one of the largest HVAC manufacturing and refrigerant companies in the world.

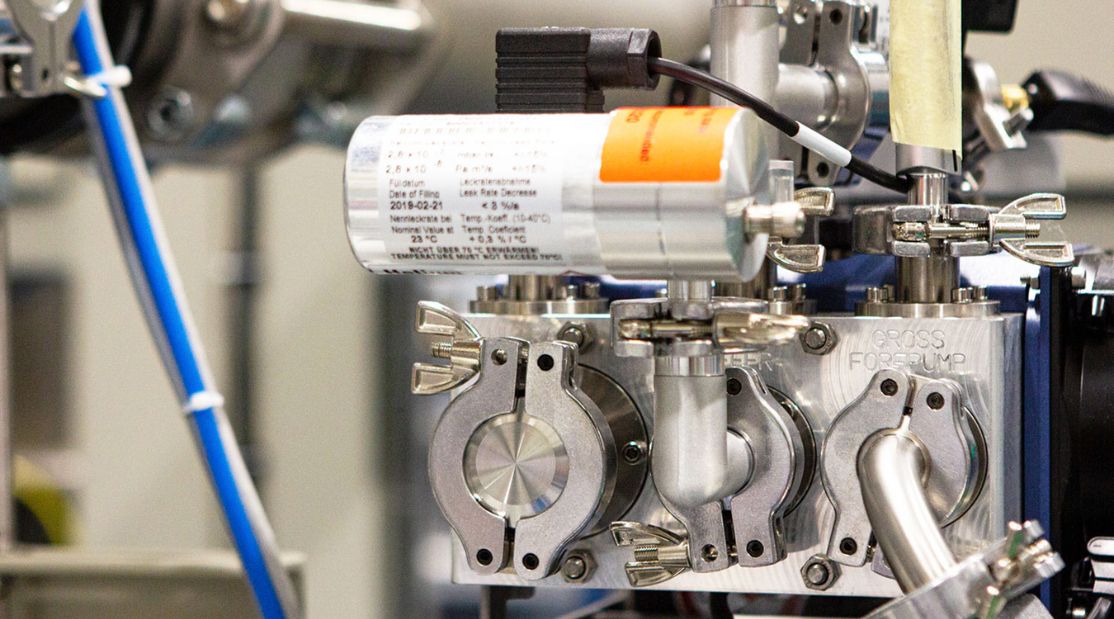

Key features of the system include a hard-vacuum leak test chamber, shaped to accommodate a variety of aluminium coil sizes. The chamber has a vertical lid closure mechanism, allowing easy access for loading and ensuring a secure seal for testing. Designed with fast production rates in mind, the system is ergonomic, enabling operators to position the coils safely and easily. After positioning, they can connect the coils to a coupling and initiate the test. For coils that don’t meet the initial performance criteria, a sniffer repair/leak check station is also provided. The system is completed by a cost-saving helium recovery station.

Currently, various systems are in different stages of production at VES. The first system has completed its final checks during a Factory Acceptance Test to ensure it meets stringent leak-tightness regulations before leaving our Manchester facility.

The well-known customer already has several of these leak testing systems in the USA. This new batch is destined for an advanced manufacturing facility in Mexico, where they will be integrated into the product assembly process. Our local engineering team will handle installation, commissioning, and provide on-site training and ongoing support.

For assistance with our advanced HVAC leak detection systems and customised solutions, contact us for more information.