As the global push for clean energy intensifies, hydrogen mobility is emerging as a solution for sustainable transportation. However, the adoption of hydrogen as a fuel source introduces stringent regulatory requirements and standards for safety, particularly in leak testing. Ensuring compliance with these regulations is essential for manufacturers of composite hydrogen pressure vessels (HPVs) and other hydrogen storage solutions. This article explores the regulatory landscape and highlights the importance of rigorous leak testing in meeting safety and environmental standards.

Understanding Regulatory Requirements

- European Pressure Equipment Directive (PEDG1) The Pressure Equipment Directive (PED) is a key regulatory framework in the European Union, ensuring the safety of pressure equipment. It mandates that individual items of pressure equipment undergo conformity assessment and CE marking. PED compliance is mandatory for manufacturers who wish to market their products within the EU.

Group 1 of the PED covers fluids classified as explosive, extremely flammable, highly flammable, flammable (with a maximum allowable temperature above the flashpoint), very toxic, toxic, and oxidising. For hydrogen pressure vessels, adhering to PED regulations ensures that they meet essential safety requirements, protecting consumers from unsafe products.

- Pressure Equipment (Safety) Regulations 2016 (PE(S)R) Following Brexit, the UK adheres to its version of the PED, known as the PE(S)R. These regulations govern the design, manufacture, and conformity assessment of pressure equipment with a maximum allowable pressure greater than 0.5 bar, ensuring that products placed on the GB market are safe.

- Korea Gas Safety Corporation (KGS) In South Korea, the KGS oversees the safety of gas-related products. Manufacturers must obtain KGS Factory Registration to export pressure equipment to Korea. This certification, issued after a thorough technical review and factory audit, ensures that products meet South Korea’s stringent safety and quality standards. With the Hydrogen Act, South Korea has identified hydrogen as a key growth area, making KGS certification essential for hydrogen pressure vessels.

- High Pressure Gas Safety Institute of Japan (KHK) Japan’s KHK standards provide comprehensive guidelines for high-pressure gas safety, mandated by the High Pressure Gas Safety Act. Products imported into Japan must pass KHK inspections to ensure safety. KHK certification is particularly relevant for hydrogen pressure vessels, given Japan’s proactive stance on hydrogen fuel cell vehicles and infrastructure.

- American Society of Mechanical Engineers (ASME) ASME standards are widely recognised and used globally for the design, construction, maintenance, and alteration of pressurised equipment. While ASME standards are voluntary, they become mandatory when incorporated into business contracts or regulations. The ASME Boiler and Pressure Vessel Code (BPVC) is particularly relevant for hydrogen pressure vessels, providing robust guidelines for safety and quality.

- China Special Equipment Licensing Office (SELO) In China, the SELO licence is mandatory for pressure vessels, hydrogen products, and valves. This certification, governed by the China Special Equipment Inspection and Research Institute (CSEI), ensures compliance with China’s safety regulations. SELO certification is necessary for manufacturers targeting the Chinese market, facilitating the safe distribution of hydrogen storage solutions.

Key Regulations and Compliance Strategies

- R134 and TCATSI 02 007-2020 R134 is an international standard that specifies requirements for hydrogen fuel tanks and systems, ensuring safety and performance. TCATSI 02 007-2020 is a technical code in China that outlines the safety standards for hydrogen storage and transportation. Compliance with these standards is essential for manufacturers aiming to enter global markets, as they ensure that hydrogen pressure vessels meet stringent safety and performance criteria.

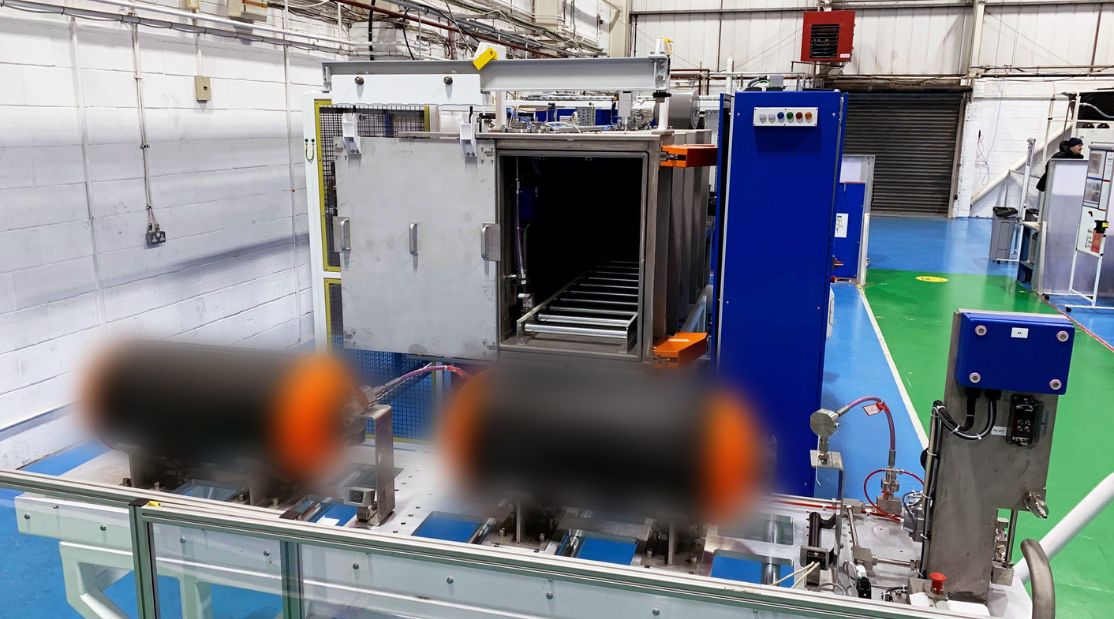

- Comprehensive Leak Testing Leak testing is a cornerstone of regulatory compliance for hydrogen pressure vessels. Rigorous leak testing methods, such as those offered by VES, provide precise and reliable detection of leaks, ensuring that pressure vessels adhere to international standards like R134 and TCATSI. The VES Leak Testing System is designed to meet these standards, offering advanced leak detection using forming gas, helium blend, or nitrogen. This system is modular and scalable, allowing manufacturers to customise their testing solutions to meet production demands while ensuring compliance.

- Pressure Regulation Compliance Ensuring compliance with diverse international pressure regulations is a complex task. Manufacturers must navigate various regional standards, each with its own requirements. Our system is designed to facilitate this process, providing guidance on international pressure regulations and ensuring that products meet the necessary standards for safety and performance. This support is essential for manufacturers looking to expand into new markets and maintain compliance with evolving regulations.

The Role of Rigorous Leak Testing

Leak testing plays a vital role in meeting safety and environmental standards for hydrogen pressure vessels. It ensures the integrity and safety of these vessels, preventing leaks that could lead to catastrophic failures or environmental harm.

Our leak testing solutions are designed to provide accurate, repeatable, and reliable results, ensuring that hydrogen storage solutions meet the highest standards of safety and compliance.

By integrating advanced leak detection methods and adhering to international standards, we work alongside manufacturers to ensure they ship their products with confidence. The turnkey, modular design of our System allows for cost-effective customisation and scalability, adapting to evolving production needs without additional investment. This flexibility, combined with comprehensive regulatory support, makes VES an ideal partner for manufacturers navigating the hydrogen mobility market.

Meeting Hydrogen Mobility Standards with Confidence

Navigating the regulatory landscape of the hydrogen mobility market requires a thorough understanding of international standards and rigorous leak testing processes. By ensuring compliance with regulations like PEDG1, KGS, KHK, ASME, and SELO, and adhering to standards such as R134 and TCATSI, manufacturers can guarantee the safety and integrity of their hydrogen pressure vessels. Our innovative leak testing solutions provide the precision, reliability, and regulatory support needed to meet these challenges, fostering a safer, more sustainable hydrogen economy.